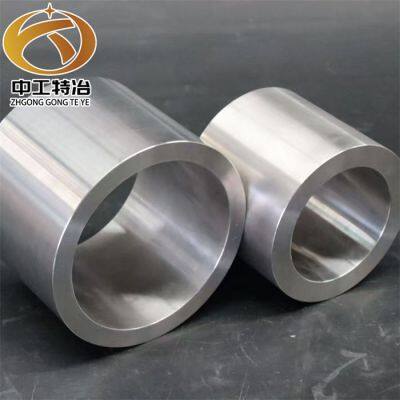

High Temperature L605/GH605 Cobalt-based Alloy Haynes25 Light Bar Forging Light Round Steel GH5605 Bright Bar

The chemical composition of L605 cobalt-based alloy is mainly composed of cobalt (Co), chromium (Cr), tungsten (W), molybdenum (Mo), nickel (Ni) and other elements. Among them, cobalt, as a matrix element, has a content of more than 50% and is the main source of alloy strength. The addition of chromium significantly improves the corrosion resistance and oxidation resistance of the alloy, enabling it to maintain stable performance in harsh environments. The addition of tungsten and molybdenum further enhances the high-temperature strength and hardness of the alloy, allowing it to maintain excellent performance at high temperatures. In addition, the alloy also contains a small amount of iron (Fe), manganese (Mn), silicon (Si) and other elements to adjust the mechanical properties and processing properties of the alloy.

1. Performance characteristics

1. High temperature performance: L605 cobalt-based alloy has excellent high temperature strength and stability, and can maintain stable mechanical and chemical properties under high temperature environment. This makes it have important application value in the manufacture of high temperature parts in the fields of aerospace, energy, chemical industry, etc.

2. Corrosion resistance: The chromium element in the alloy gives L605 cobalt-based alloy excellent corrosion resistance, especially for oxidizing acid and high temperature oxidizing atmosphere. Therefore, it has a wide range of application prospects in corrosive media environments such as petroleum and chemical industry.

3. Wear resistance: L605 cobalt-based alloy has high hardness and good wear resistance, and can maintain a long service life under high load and high friction conditions. This gives it obvious advantages in the manufacture of moving parts such as engine valve seats and piston pins.

4. Formability: L605 cobalt-based alloy has good formability and can be processed into various complex shapes of parts through forging, rolling, welding and other processes. This provides strong support for the application of alloys in high-end manufacturing fields such as aero engines and spacecraft.

Send Inquiry to This Supplier

You May Also Like

-

Versatile High Hardness UNS R30012 Cobalt Base Alloy Stellite 12 Alloy Rods Sheets TubesNegotiableMOQ: 1 Ton

-

8.6g/cm3 Cobalt Based Alloys Wear Resistant Stellite 23 AlloyNegotiableMOQ: 1 Ton

-

55 HRC -60 HRC Cobalt-based Alloy Stellite 21 High Temperature Resistant Alloy Rods, Plates, Tubes High Quality MaterialNegotiableMOQ: 1 Ton

-

Corrosion-resistant Stellite 6 Low-ductility Stellite 6B for Cutting ToolsNegotiableMOQ: 1 Ton

-

53 HRC - 60 HRC Cobalt Based Alloys Corrosion Resistant Stellite1 Stellite3 Stellite6 Alloy Round Steel Bars High QualityNegotiableMOQ: 1 Ton

-

Stellite Alloy Hot-rolled Sheet Cobalt Alloy Sheet Stellite20,Stellite4,Stellite8NegotiableMOQ: 1 Ton

-

Stellite 6 Alloy Plates/bars, Cobalt-based Solid Solution Steel Pipes, Stellite8 Round SteelNegotiableMOQ: 1 Ton

-

Stellite Alloy Bars Stellite4 Stellite8 Cobalt Based Alloy Stellite31 Stellite100NegotiableMOQ: 1 Ton

-

Customized Cobalt Base High Temperature Resistance MP159 Alloy Solid Round BarNegotiableMOQ: 1 Ton

-

Customized Wear-Resistant High-Temperature Resistant 3J21 Precision Alloy Pipe/SheetNegotiableMOQ: 1 Ton